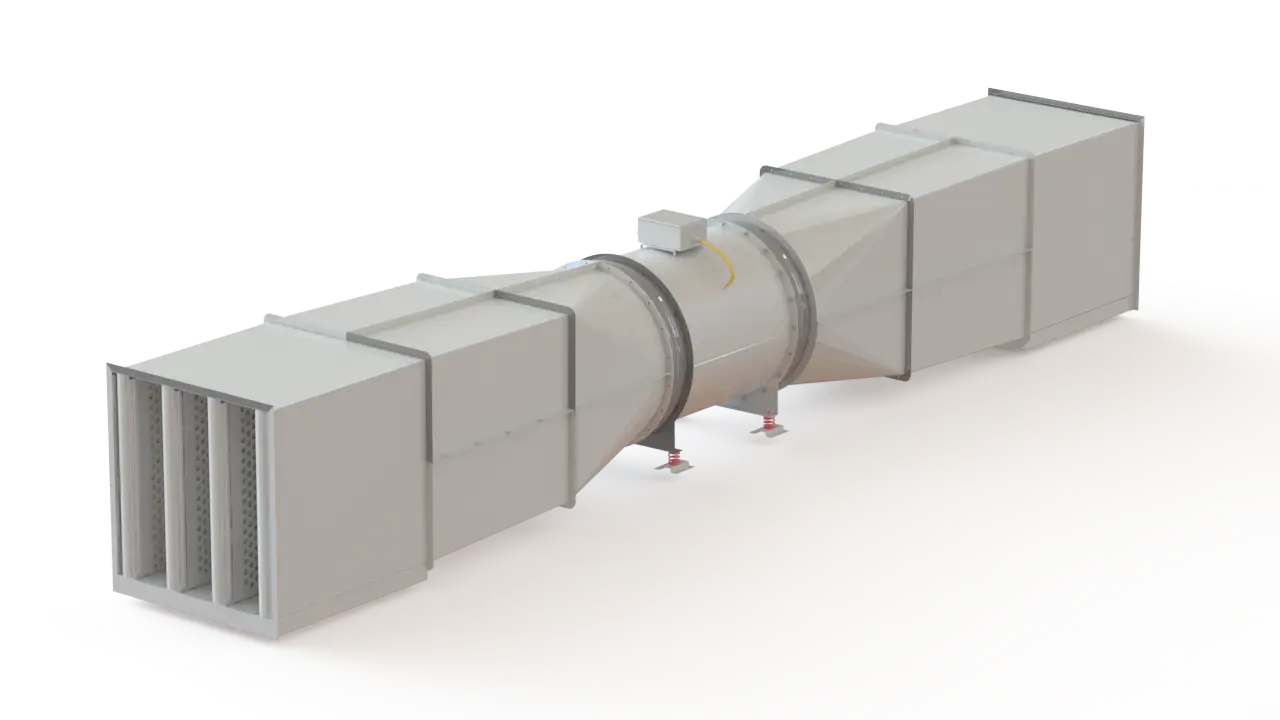

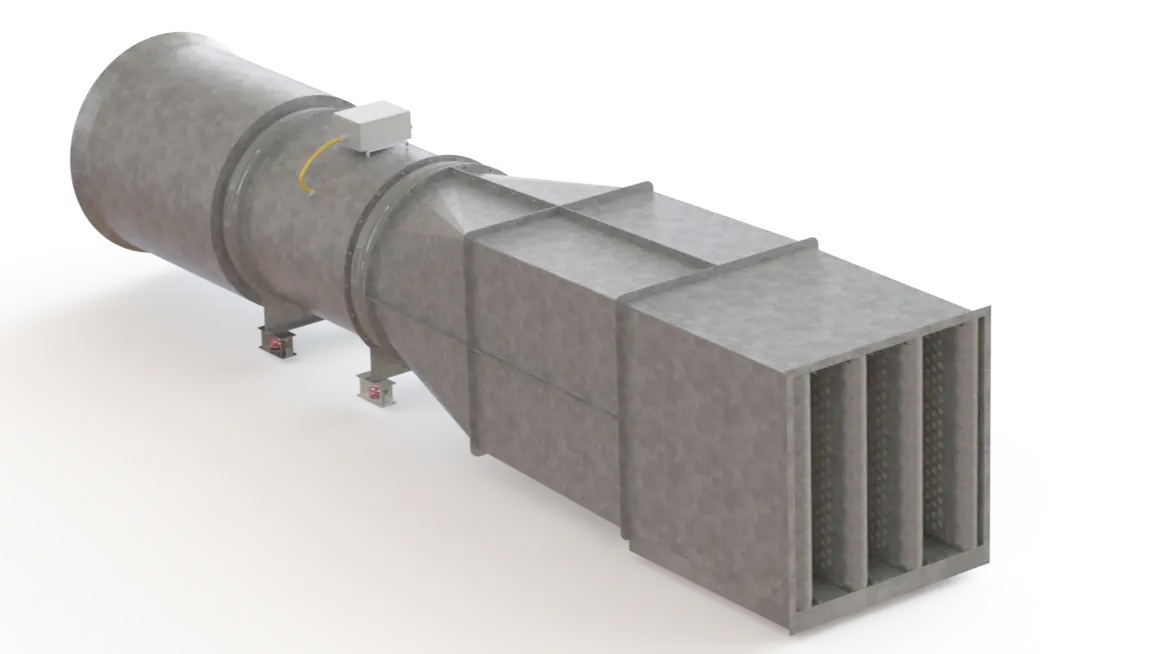

Metro Tunnel & Station Ventilation Systems (TVF – OTE – UPE)

Fan Functions for Emergency and Normal Tunnel Ventilation

TVF - Tunnel Ventilation Fan

- Purpose: Main fan used in tunnels to manage airflow for both normal operation and emergency smoke extraction.

- Function: Ensures proper air exchange, smoke control, and temperature management.

- Key Feature: High temperature resistance and bidirectional airflow capability for emergencies.

OTE – One-Time Exhaust Fan

- Purpose: Designed specifically for emergency-only operation.

- Function: Operates once during a fire to extract smoke and toxic gases from tunnels or stations.

- Key Feature: Often sacrificial – designed to function during extreme heat (e.g. 300–400°C) for up to 2 hours and may not be reusable afterward.

UPE – Unidirectional Pressurization Exhaust Fan

- Purpose: Used to pressurize escape routes such as evacuation shafts or stairwells and to assist smoke extraction.

- Function: Helps prevent smoke from entering safe zones by creating positive pressure in designated areas.

- Key Feature: Usually runs in one direction and is part of a broader pressurization system.

Reliable Ventilation Solutions for Critical Transit Infrastructure

Certified Metro & Tunnel Fans for High-Temperature Operation

EMAK Metro and Tunnel Fans (TVF, OTE, UPE) are fully compliant with NFPA 130 standards and are designed for high performance in critical transit ventilation applications. These fans offer key advantages including high efficiency, long service life, quiet operation, low maintenance requirements, and a wide range of sizes—with diameters up to Ø 3550 mm—to accommodate large air volumes at relatively low static pressures.

EMAK’s fully reversible fan models are specifically engineered to operate under high-temperature conditions (200°C, 300°C, and 400°C) and are tested in accordance with internationally recognized standards for fire and smoke control.