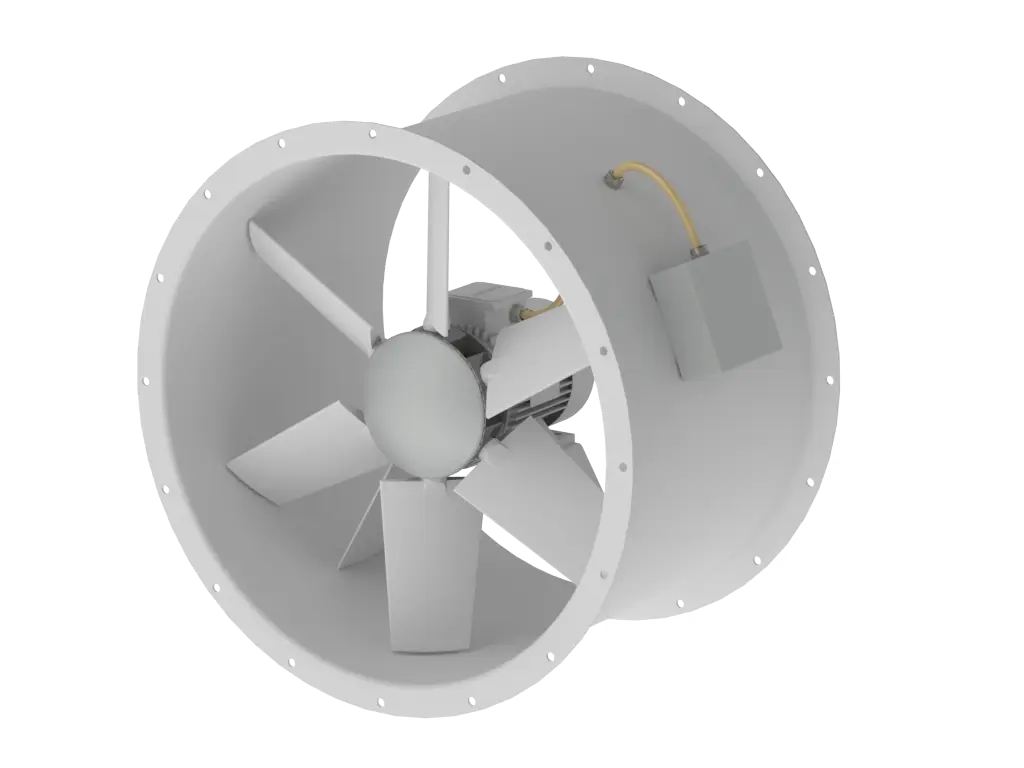

TAM Series Axial Fans

We make every moment count with solutions designed just for you.

Application

The TAM industrial extraction unit is engineered for continuous operation in extreme environments, delivering high-performance airflow across a temperature range of -20°C to 55°C. It is ideal for industrial facilities, manufacturing plants, and processing applications where operational reliability is essential.

Performance

The TAM fan is factory-tuned with a precisely set blade pitch angle, ensuring it meets specific airflow and pressure requirements. This approach delivers a wide performance range and simplifies system integration. For applications requiring enhanced output, an optional guide vane is available to improve pressure performance and operational efficiency.

Sturdy and Dependable Design

Built for long-term performance, the TAM features corrosion-resistant impellers made of aluminum, steel, or plastic, high-efficiency motors compliant with current EU standards, and a casing constructed from mild steel S235JR (EN 10025), available in stainless, pre-galvanized, or optionally hot-dip galvanized finishes for enhanced corrosion protection, depending on project requirements. These components ensure durability, high quality, and a long service life, even in demanding industrial environments.

Flexibility

The TAM fan can be customized to meet your specific needs with a variety of options, including:

- A wide range of accessories

- Multiple coating colors

- Special motor versions (e.g., rated up to 100°C, with corrosion protection C5, or for different voltages)

- Factory Acceptance Testing (FAT) for project validation

- Optional noise reduction using the TAM-HAF

- Casings available in stainless steel or with shorter lengths

- Flexible terminal box positions

- X-ray tested blades and hubs for enhanced quality assurance

Tested According to ISO 5801 and AMCA 210 Standards

TAM axial fans have been performance tested in accordance with ISO 5801 (2007) and AMCA 210 standards at EMAK’s in-house laboratory, using standardized fan test rigs. These procedures ensure accurate and reliable airflow and pressure ratings.

Note: TAM fans are not AMCA certified, but are tested according to AMCA 210 methods.

Certified for CE and EU Compliance

TAM fans comply with essential European Union directives and standards and are certified by Bureau Veritas under CE attestation, including:

- Machinery Directive 98/37/EC

- Low Voltage Directive 73/23/EEC

- EMC Directive 89/336/EEC

Tested and evaluated under multiple standards:

- ISO 5801 for fan performance

- ISO 21940 for rotor balancing

- BS 848-1, BS EN 12101-3, ISO 1940, and AMCA 99-3001 for design and testing benchmarks

The impellers are balanced to G6.3 or G2.5 quality grades to ensure low vibration and high durability.

Technical Specifications

We make every moment count with solutions designed just for you.

Casing

The casing is made from hot-dip galvanised steel according to ISO 1461 with pre-drilled flanges. The terminal box with IP 65 is mounted outside on the casing.

Impeller

The impellers are made of aluminum and are dynamically balanced in accordance with ISO 21940-11, balancing quality G6,3, and vibration limits according to ISO 14694.

Motor

Standard models are driven by three-phase AC motors with efficiency IE3 suitable for 50Hz and optionally for 60Hz.

Motor Protection

The motors are equipped with PTC thermistors for motor protection.

Control

Motors can be speed controlled by frequency inverter between 10 and 60 Hz.

Installation

The TAM fans can be installed in different positions indoor and outdoor (for more information see the manual).

Recommended accessories: flexible connections, vibration dampers, mounting feet.

Control

Motors can be speed controlled by frequency inverter between 10 and 60 Hz.